Netstock – Supply chain planning software

Make better inventory decisions with Netstock’s AI-powered, cloud-based, supply chain planning software.

Netstock – Predictive Planning Suite

Download nowWith the right inventory in the right place at the right time, growing your business has never been easier with Netstock — an affordable cloud solution that helps companies to:

Produce orders in minutes

Increase the effectiveness and efficiency of the replenishment process

Minimise stock-outs

Proactively avoid stock-outs, retain customers and increase sales

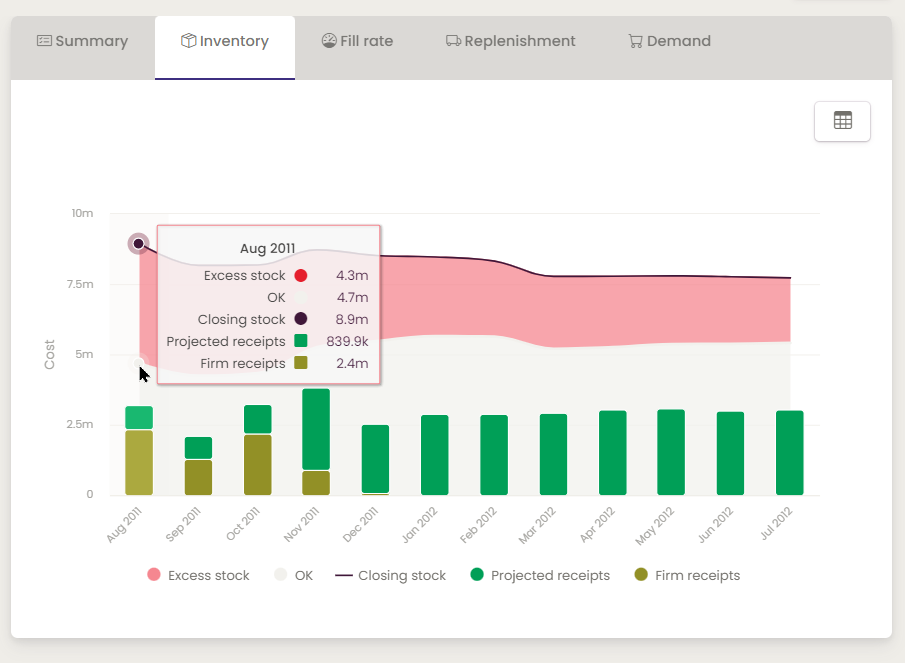

Reduce excess inventory

Release the cash that is tied up in excess inventory, and avoid excess creation

Benefits of Netstock for inventory management

What to expect from Netstock:

- Reduce inventory by up to 35%, reduce working capital and improve cash flow

- Improve fill rates by up to 15%, minimise stock-outs and increase sales

- Significantly reduce the time spent on planning, forecasting and ordering

- Unprecedented inventory visibility, including early warning of items needing attention

- Better supply chain management, optimising your supply in the face of changing lead times

- The right inventory in the right place at the right time, helping you to grow your business

Netstock is a game-changer for your business. The Netstock supply chain planning solution will analyse data in your ERP and provide actionable insights to drive smart decisions across your business. Find out the three steps to optimise your inventory.

See Netstock for yourself

Watch an introduction to Netstock and see how you can optimise your inventory.

Key Features of Netstock

Sales & Operations Planning

- Alignment of sales, operations, procurement, and finance,

- Reporting and interactive dashboards,

- Alignment of strategic, tactical, and operational timeframes.

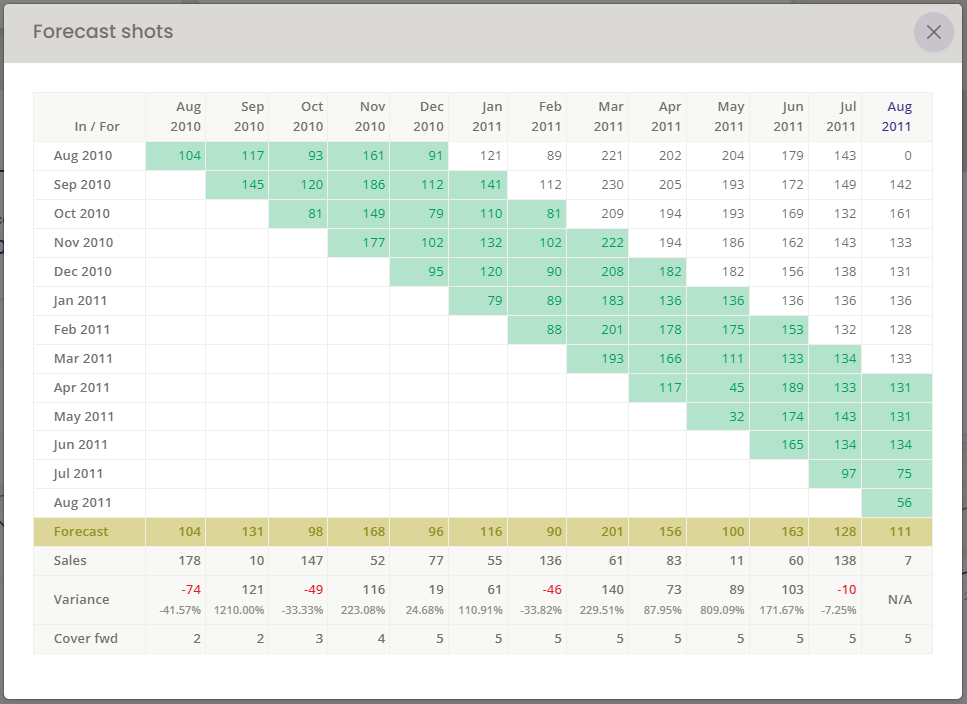

Forecasting & Demand Planning

- Customer and channel segmentation,

- AI & ML-based forecasting, monthly, weekly, or daily,

- Get ahead of market-wide demand planning trends with real-time insights

- Promotions, events, seasonal and non-seasonal indexes.

Inventory Optimisation

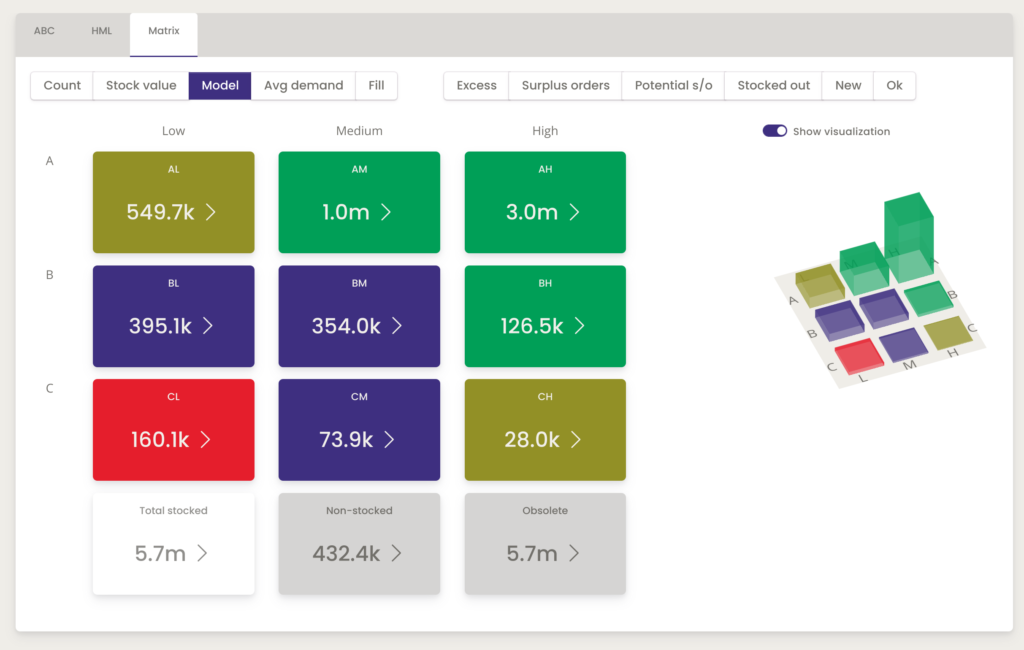

- Segmentation & Classification,

- Inventory policy modelling & risk analysis,

- Scenario comparisons.

Replenishment & Distribution Planning

- Auto-generation of purchase orders, transfers, and production orders,

- Prioritise business-critical orders,

- Forward ordering and container optimisation.

Manufacturing & Capacity Planning

- Alternative sourcing,

- Level loading,

- Multi-level bills of materials, resources, and kits.

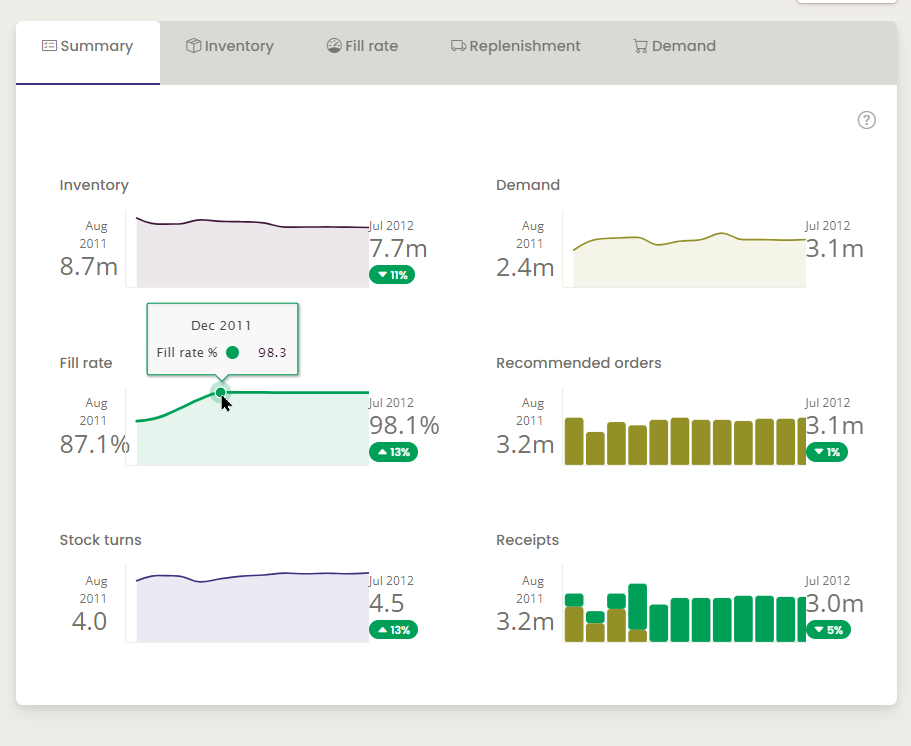

Performance Analysis

- Inventory KPIs and dashboards to monitor supply and demand,

- Comparisons of theoretical versus actual stock,

- Supply and demand exceptions and root cause analysis.

Learn about how All-Round Supplies save time with Netstock

Netstock Screenshots

About Netstock

Netstock is a leader in predictive supply chain planning software. They are trusted by more than 2,200 customers globally to place optimal orders, reduce stock-outs, and minimise excess stock. Netstock’s AI-powered cloud-based solution synchronises demand and supply insights with MYOB Advanced and MYOB Exo. It provides small to medium-sized businesses with supply chain visibility to unlock cash, respond to change, and offer exceptional customer service, delivering ROI from day one.

To find out how Netstock can benefit your organisation, email sales@kilimanjaro-consulting.com or call 1300 857 464 (AU) or 0800 436 774 (NZ).